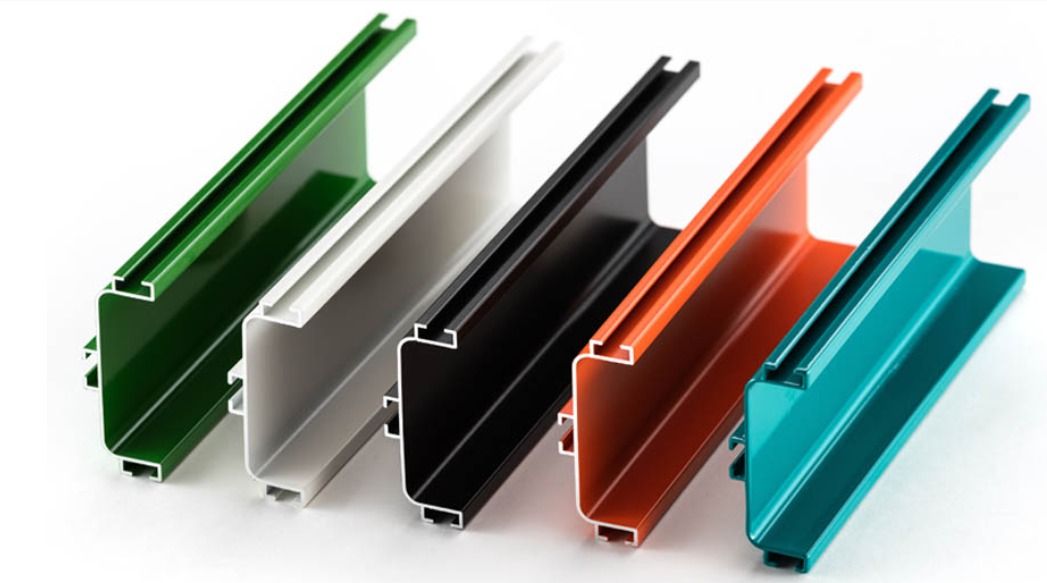

Aluminum coating is a process of depositing a thin layer of aluminum onto a surface to improve its properties. This coating can be applied to a wide range of materials,including metal, plastic, and glass. Aluminum coating is widely used in various industries, including aerospace,automotive, and electronics, among others.

One of the primary benefits of aluminum coating is its ability to improve the surface’s durability and resistance to wear and tear. The coating can also enhance the material’s resistance to corrosion, oxidation, and other forms of degradation, making itsuitable for use in harsh environments.

The process of applying aluminum coating can be achieved through different methods, including physical vapor deposition(PVD), chemical vapor deposition (CVD), and electroplating.PVD and CVD methods involve heating the aluminum to a high temperature and then depositing it onto the surface through a vacuum or gas process. Electroplating, on the other hand,involves immersing the material in a solution containing aluminum ions and then applying an electrical current to deposit the coating onto the surface.

Aluminum coating can be used for various applications, depending on the properties required. In the aerospace industry, aluminum coatings are used to protect aircraft parts from corrosion and wear. In the automotive industry,aluminum coatings can improve the performance and durability of engine components. In the electronics industry, aluminum coatings can be used to create high-performance conductors for circuit boards.

In conclusion, aluminum coating is an essential process that offers many benefits to various industries. The coating can improve the durability, resistance to wear and tear, and resistance to corrosion of the material,making it ideal for use in harsh environments. The process of applying aluminum coating can be achieved through different methods, and the choice of method depends on the specific application.